BERQUE makeSafe Earthing System

• Launched in 2009 after a 5-year R& D work carried out in consultation with qualified electrical engineers, chemical engineers, scientists, and professors from I.I.T.

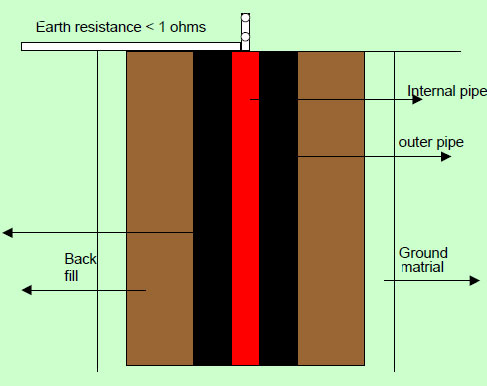

• Pipe-in-Pipe Technology

• Manufactured as per IS 3043:1987.

• Patented for its Design & Technology

Safe Earthing Electrode

• There are two pipes, one inside the other i.e., pipe- in- pipe technology

• Safe earthing electrode is not in direct contact with the soil.

• Absence of corrosion

• Least fluctuation of Ohmic value.

• Since SEE is surrounded by

highly conductive soil so the

charge dissipation through the

electrode is very high ,

sufficient to trip the fault

relays

Two ‘B’ class mild steel pipes, one inside the other, are subjected to Hot Dip Galvanization : 80 -100 micron on secondary electrode and 80 –300 micron on the primary electrode. Empty space inside the primary electrode and the secondary electrode is filled with CRYSTALLINE CONDUCTIVE MIXTURE and then sealed.

Description of Safe Earthing Electrode unit

• Red color pipe - main earthing pipe

• Outer pipe - G.I pipe

• Black color - Conductive Material (CCM)

• Earth color- Back FillCompound (BFC)

• Surrounding - Ground

• Top- Connecting Terminal

Two ‘B’ class mild steel pipes, one inside the other, are subjected to Hot Dip Galvanization : 80 -100 micron on secondary electrode and 80 –300 micron on the primary electrode. Empty space inside the primary electrode and the secondary electrode is filled with CRYSTALLINE CONDUCTIVE MIXTUREand then sealed.

Constructional features

• One G. I. Pipe placed in side outer G.I. Pipe

• Outer G.I. PIPE galvanized to 80 -100 microns for better corrosion protection and conductivity

• Highly conductive , anticorrosive Crystalline Conductive Material filled in the annular space between two pipes & inner pipe.

• The electrode while installation surrounded by special backfill material .

Crystalline Conductive Mixture(CCM)

• Contains metal alloys and natural compounds

• High conductive, Anticorrosive

• Does not disintegrate or collapse even when outer electrode becomes inactive.

The Backfill Material

Back Fill Materialis a specially developed compound, which is capable of absorbing and retaining the moisture for a long time, it reduces the soil resistivity, it helps in faster dissipation of fault current, least fluctuation of Ohmic value and it eliminates the use of Salt, Charcoal etc. around the Earthing Electrode.

It has low solubility, hence is not easily washed away, and has a low resistivity (approximately 5-10 Ohm-meters in a saturated solution).

It is virtually neutral, having a pH value of between 6.2 and 6.9. It is naturally occurring, so should not generally cause environmental difficulties in use.

It assists in maintaining a relatively low resistivity over a long period of

time, where salts in the vicinity are dissolved away by water movements (rainfall etc.). However, the fact that the material is not easily dissolved will moderate the benefits achieved, since it will not permeate far into the ground. This means that the beneficial effect will be localized for say an area excavated around a buried electrode. This in turn means that the reduction in the resistance value of the electrode will not be dramatic but will be reasonably sustainable.